Since 1973

Comprehensive service and maximum customer focus: personalised advice, transparent project planning, training.

Over 50 years of experience in vibration technology: Thanks to our long tradition in the production of external vibrators and the associated expertise, we can guarantee maximum reliability and the highest standards.

Reliable, fast and cost-effective delivery. In the case of hire equipment, we will also arrange the return delivery by prior arrangement.

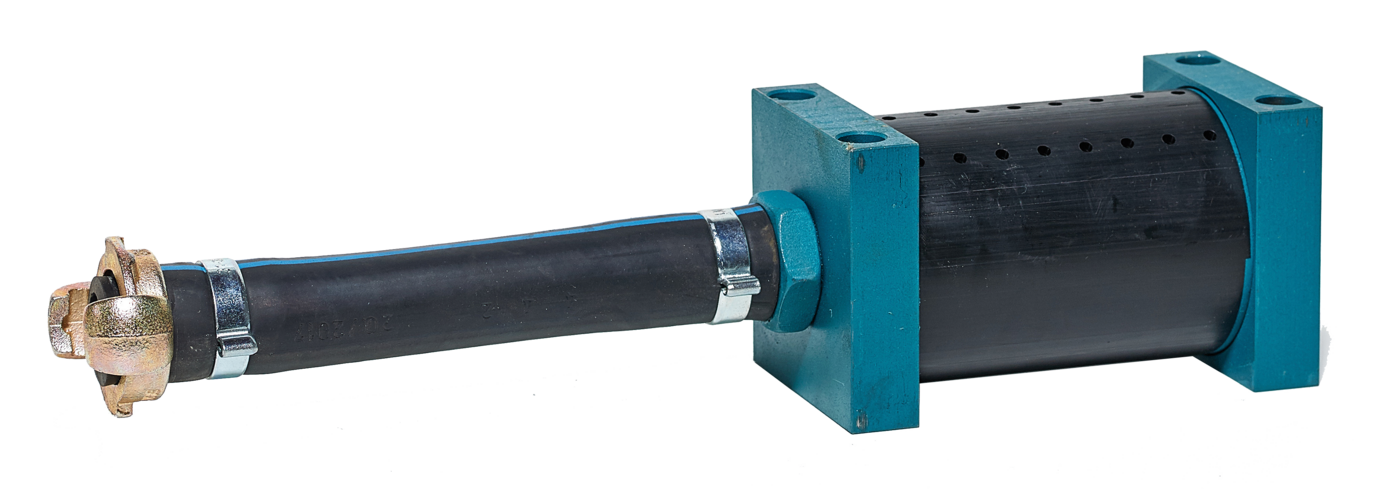

The original: Compressed air Mooser external vibrator® VR56K

The original: Compressed air Mooser external vibrator® VR57K

BENEFITS

Our compressed air Mooser formwork vibrators® guarantee reliable work and a particularly long service life, especially under the highest loads and in continuous operation. They are our solution for first-class compacted concrete and outstanding concrete surfaces.

- low weight

- simple, intuitive handling

- very robust, reliable, durable

- maintenance-free

- extremely powerful

- reach their nominal speed immediately

- can be infinitely adjusted via the air flow rate

- can be mounted very easily on the formwork thanks to their compact size

TECHNICAL DATA

| model | rotations: 1/min | centrifugal force: N | air consumption: m³/min | weight: kg |

| VR56K | 17.500 | 25.000 | 1,05 | 3,5 |

| VR57K | 14.000 | 31.500 | 1,37 | 7,5 |

Frequently Asked Questions

What compressor output is required to put the VR pneumatic vibrators into operation?

What compressor output is required to put the VR pneumatic vibrators into operation?

You need an air compressor with an air volume of approx. 4-6m³/min and an air pressure of approx. 6bar

How are the VR compressed air Mooser external vibrators® put into operation?

How are the VR compressed air Mooser external vibrators® put into operation?

An air compressor supplies the air volume required for the VR compressed air Mooser external vibrators®. The compressed air vibrators are switched on in pairs and one after the other (maximum 4 vibrators at the same time). The vibrators should only be switched on at the points where concrete is being poured into the formwork.

How are the VR compressed air Mooser external vibrators® mounted on the formwork?

How are the VR compressed air Mooser external vibrators® mounted on the formwork?

There are numerous mounting systems for the VR pneumatic vibrators, which differ depending on the formwork type. The Mooser STA bracket system with formwork-specific replacement adapter enables quick assembly changes on different types of formwork. The vibrators can be attached to the frame joint and/or the cross profile of the formwork.