External vibrator - for the creation of high-quality concrete surfaces

Since 1973

Comprehensive service and maximum customer focus: personalised advice, transparent project planning, training.

Over 50 years of experience in vibration technology: By manufacturing our products in-house, we can respond flexibly to customer requirements in order to deliver the best possible solutions.

Reliable, fast and cost-effective delivery. In the case of rental equipment, we can also arrange for return delivery.

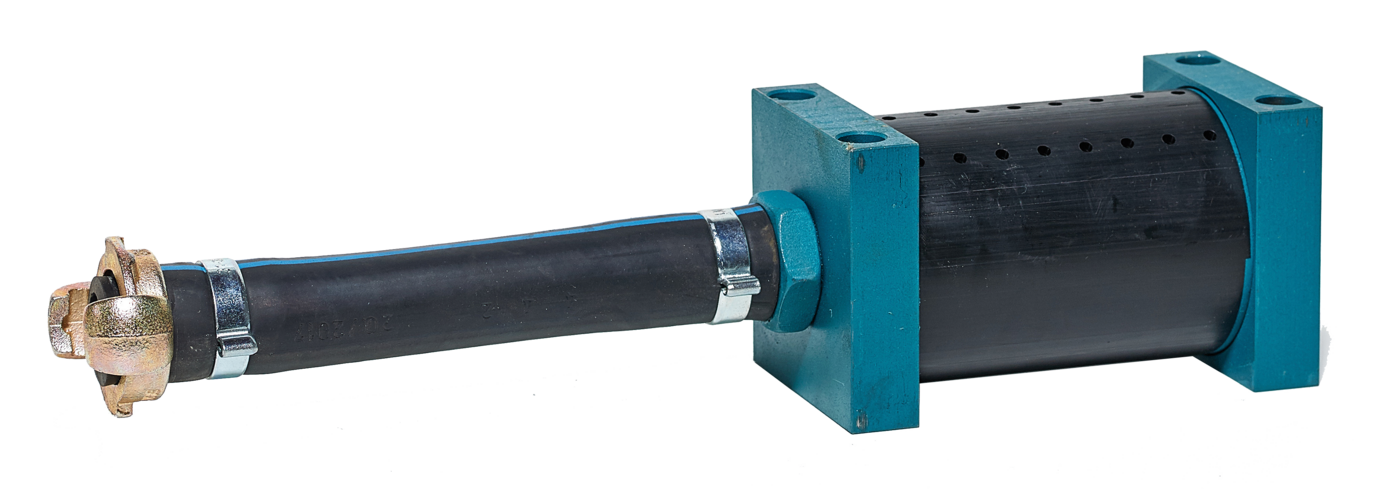

Pneumatic External Vibrator VR56K

Our VR formwork vibrators: powerful, robust and durable. They are external vibrators with a compact size and low weight, ideal for any construction project in tunnelling, building construction, industrial construction or bridge building. The infinitely variable frequency control enables easy handling and optimum concreting and compaction of in-situ concrete. The external vibrators are low-maintenance and reliable. The VR pneumatic external vibrator immediately reaches its nominal speed when the air supply is switched on and passes through the formwork's natural frequency range abruptly - so there is no risk of damaging the formwork. Perfect for concrete compaction under tough operating conditions and our vibration technology solution for the best concrete production and your construction project.

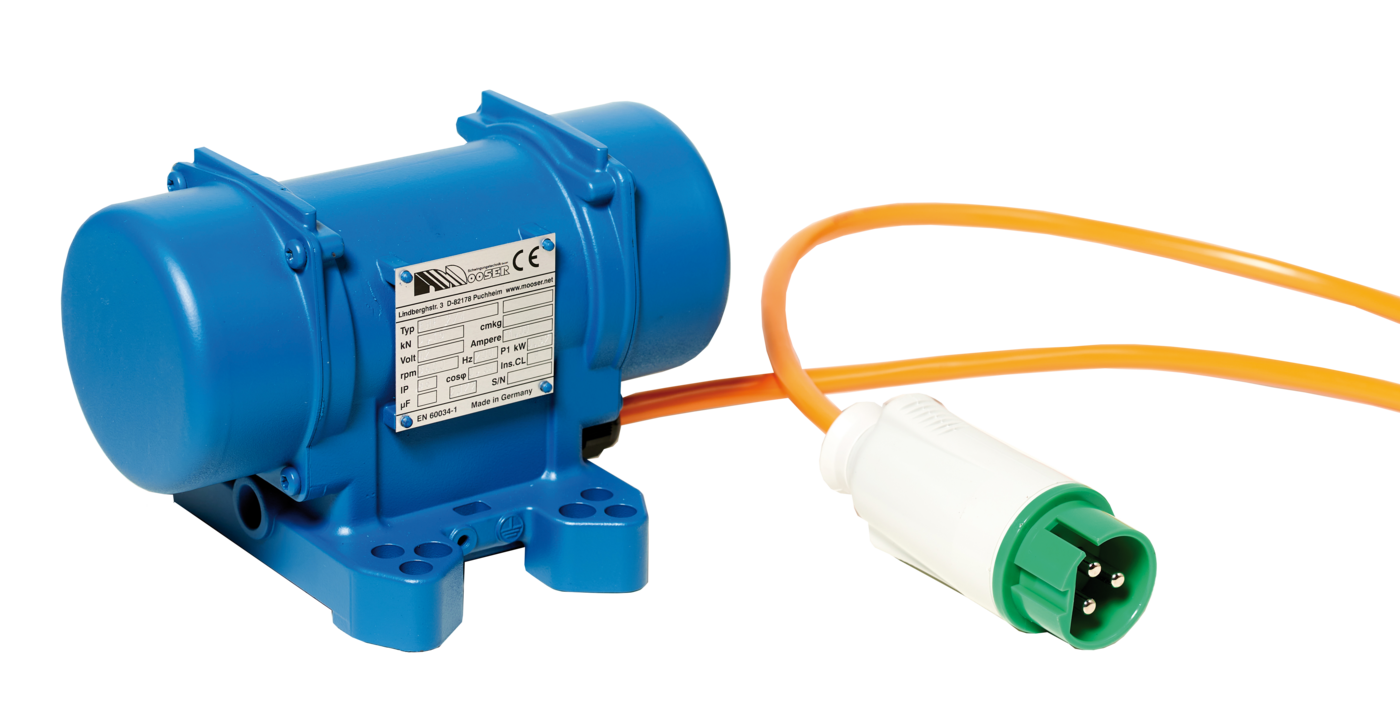

Electric External Vibrator

Electric external vibrators guarantee optimally compacted concrete and smooth surfaces. Robust design for high operational reliability and long service life. Maintenance-free and easy to mount on the formwork. First-class material for long-lasting performance. Perfect for concrete compaction.

Mounting Clamps for External Vibrators

With our mounting systems for our external vibrators, you have the right solution for all common types of formwork. Our STA universal bracket offers particularly flexible application options with formwork-specific adapters. Quick and easy to replace depending on the formwork type and area of application. Easy installation of the external vibrators, securely and firmly attached to the formwork. Quick changeover to another formwork system thanks to replacement adapter. Protects the formwork beams

Benefits - Mooser External Vibrators

Our external vibrators are the solution for creating first-class concrete surfaces on challenging engineering structures:

- robust, reliable, durable

- high-quality materials

- powerful

- easy to handle

Frequently Asked Questions

Where external vibrators are needed?

Where external vibrators are needed?

- for a high degree of reinforcement

- for exposed concrete requirements

- for very high or very thick walls

- for inclined walls

- underneath wall recesses

- for tunnelling, bridge and building construction

For which formwork systems are external vibrators suitable?

For which formwork systems are external vibrators suitable?

Our external vibrators are suitable for almost any formwork. The vibrators can be mounted onto wall formwork (frame and girder formwork), column formwork or underneath slab formwork and onto steel formwork. The right mounting system plays an important role. If no suitable fastening option is available for a formwork, we will develop a suitable solution.

Which concrete consistencies are suitable for optimum compaction with external vibrators?

Which concrete consistencies are suitable for optimum compaction with external vibrators?

We recommend concrete consistencies from Eurpean class F4 concrete with a slump of about 160mm for optimum concrete compaction.

What are the usual distances between external vibrators for in-situ concrete compaction?

What are the usual distances between external vibrators for in-situ concrete compaction?

The distances between the external vibrators depend on the construction and formwork geometry and the concrete consistency.

For F4 concrete consistency (slump of about 160mm) and wall thicknesses of up to 50 cm, external vibrator spacings of approx. 1.0 m to 1.35 m are usual. The stiffer the concrete, the closer the external vibrators should be mounted to the formwork.

For your project, please always contact Mooser Schwingungstechnik

or your external vibrator supplier for a customised vibration scheme for your project.